Process Samples

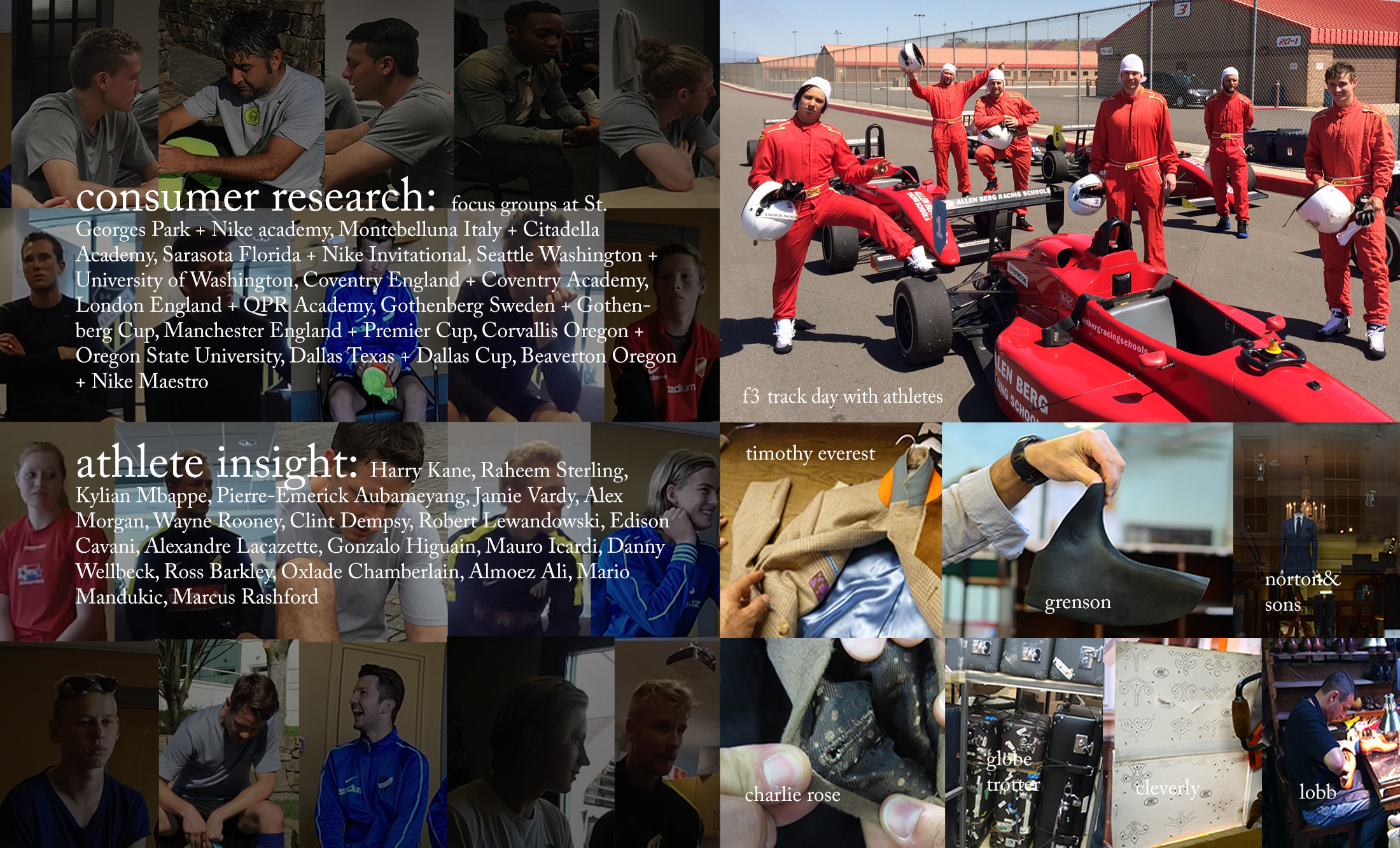

CONSUMER RESEARCH/INSIGHT: (Left) Focus groups and athlete insight gathering for the Nike Hypervenom III and Phantom VNM. (Top right) Athlete experience to inspire moonshot thinking about skateboarding. (Bottom right) Tour of English craft for Nike SB Hybred Boot. (Not shown) Internet research including current market, relevant social media, and product reviews.

NARRATIVE: (Left) Hypothetical question establishing Nike Utility ADV direction; what would be the best bag if Tokyo was in the mountains of Hokkaido? (Right) Mantra for backcountry goggle project.

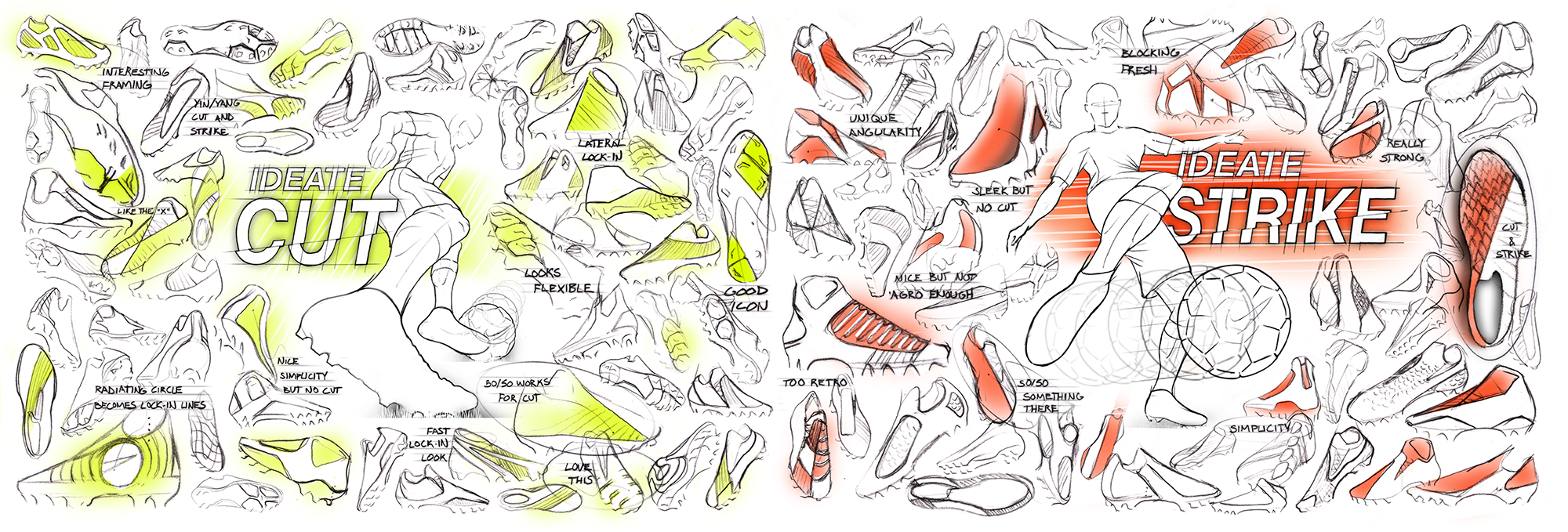

IDEATION: Nike Hypervenom III thumbnail drawings.

SKETCHING: (Left) Automotive concept sketches. (Right) Nike Phantom VNM final direction sketches.

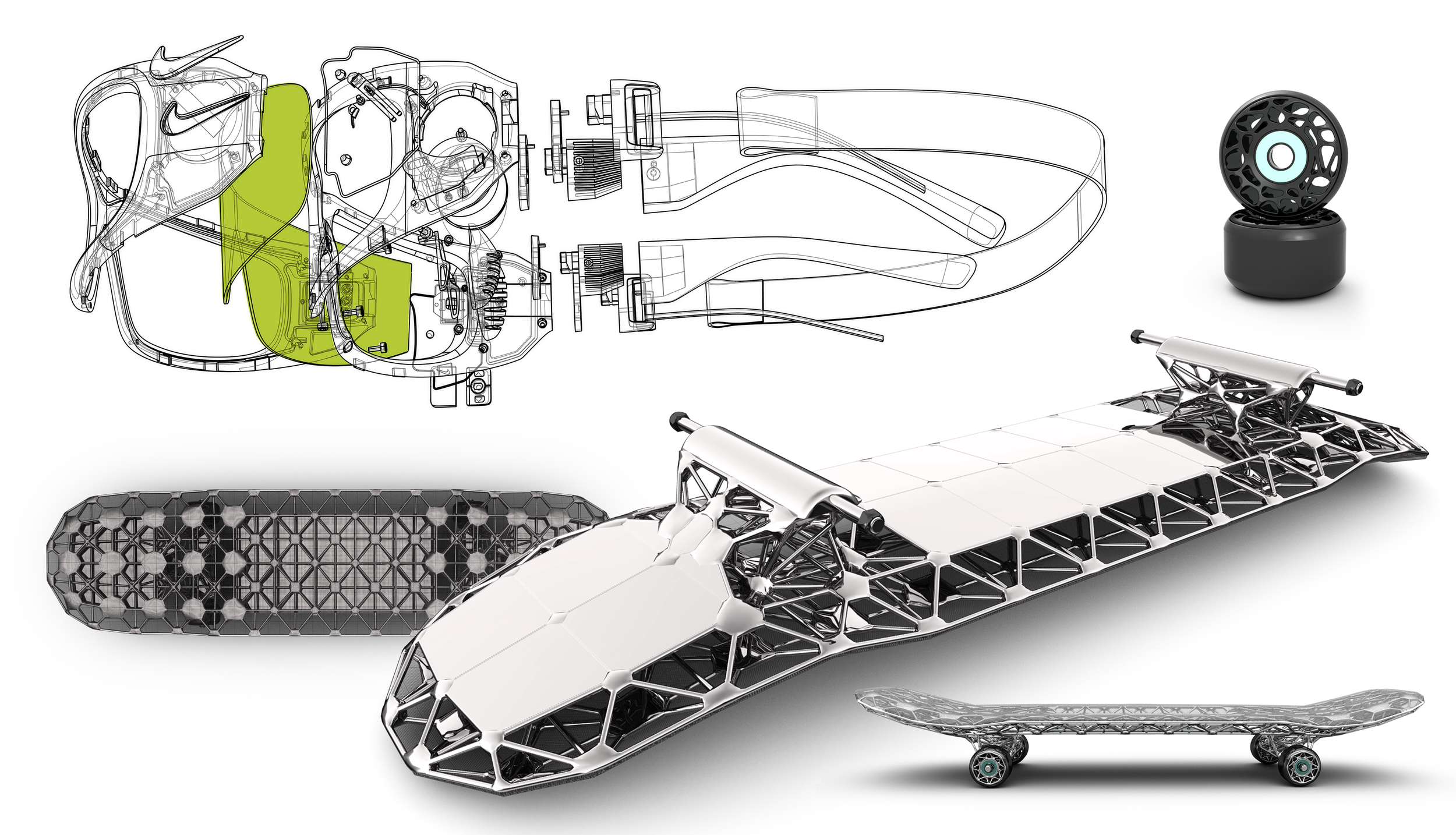

3D MODELING: Experienced in many 3D software platforms. (Top) Parametric 3D modeling and engineering of Nike Strobe. (Bottom) Generative/computational model of printed skateboard.

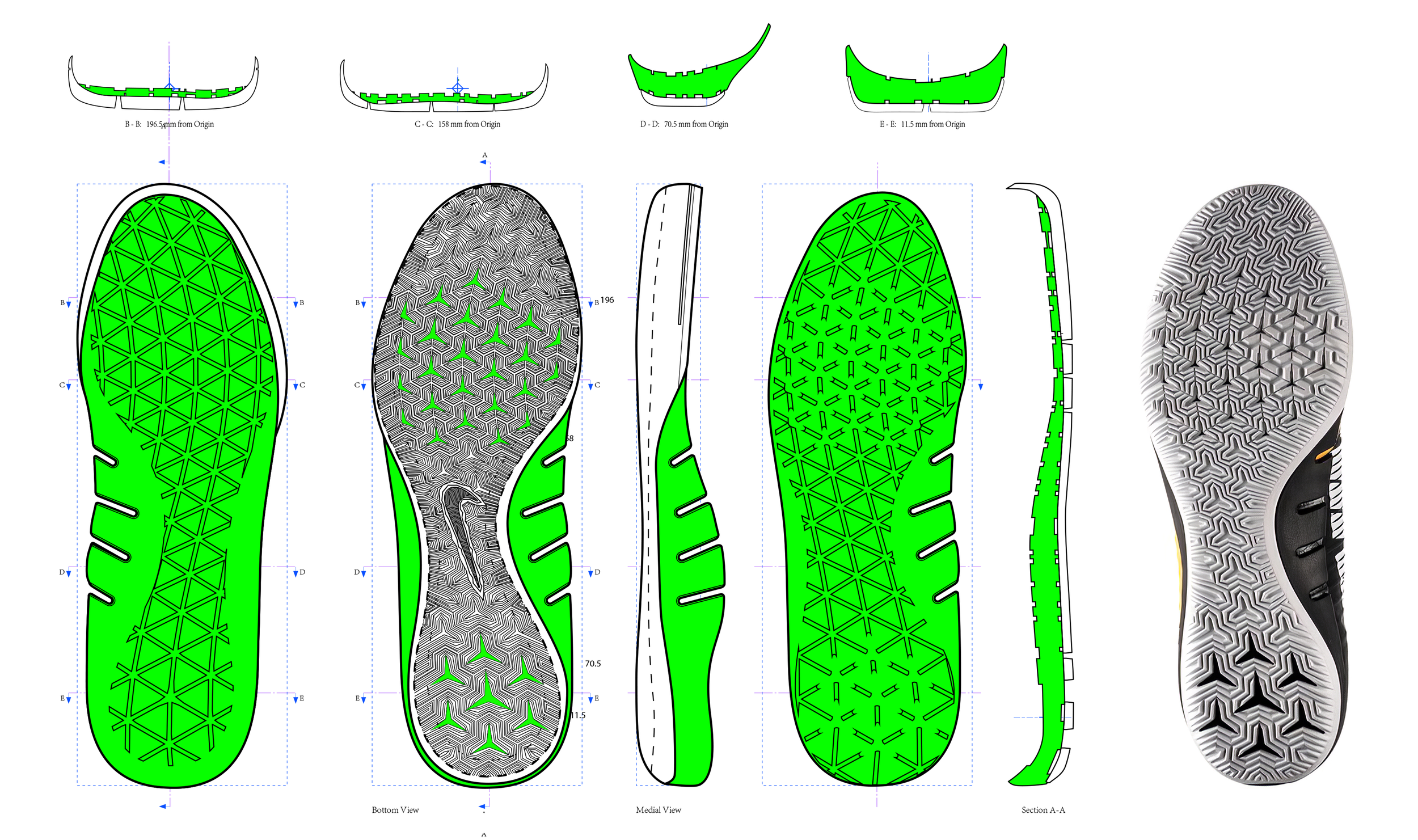

TECHNICAL DRAWING: Nike Mercurial Finale IC midsole and outsole tech pack and (right) confirmed production midsole outsole.

MAKING: (Left) Hand-made (upper/bootie) original prototype of the Nike SB Hybred Boot. Required patterning, stitching, heat pressing, ultrasonic welding, strobel stitching, and sole laying. (Right) Hand made clear polycarbonate skateboard (board only), used to gain insight and validate the Nike SB Skate Free. Due to thickness, required heating to 250°F for three days before heating to 350°F and bending to avoid air bubbles. (Not shown) 3D printing is a critical tool in this stage.

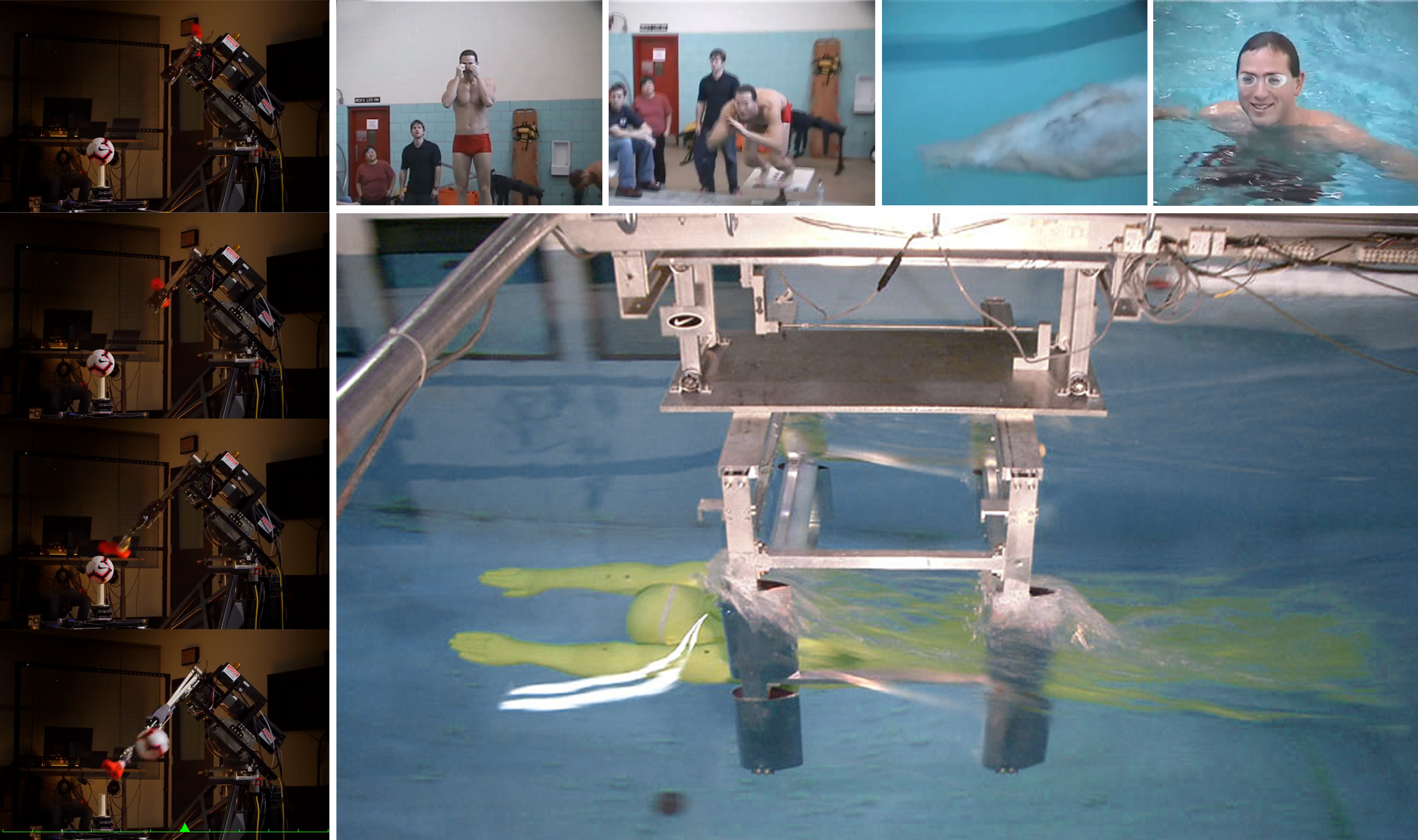

DATA GATHERING/TESTING: (Left) Robotic kicking machine testing the Nike Phantom VNM for power, accuracy, and consistency. (Top right) Olympic gold medalist swimmer testing the Nike Swift Swim Strapless Goggle. (Bottom right) Hydrodynamic testing of Nike Swift Swim goggles and cap in a specially designed tow tank at the University of British Columbia. (Not shown) Wear-testing can be the final confirmation step in the process or cycle back to the beginning.